Oriented Wires in Silicone

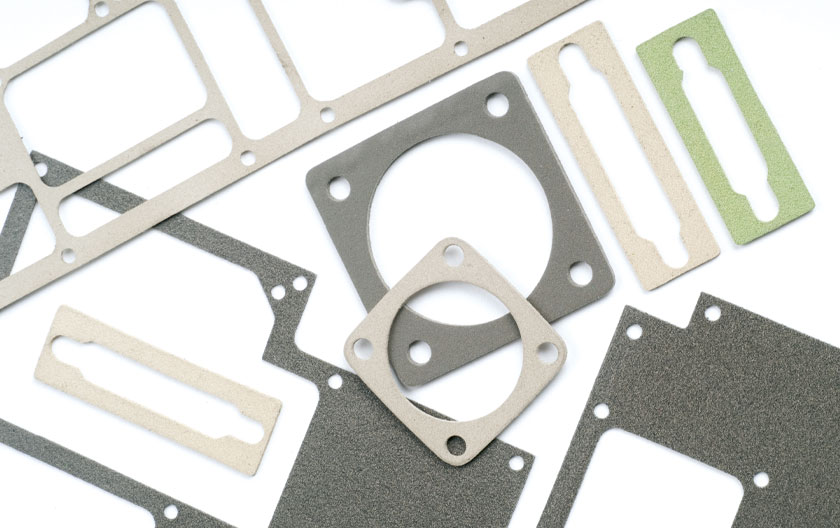

Solid and sponge silicone flat gasket material populated with vertically oriented Monel or aluminium wires up to 140/sq cm. Provides excellent shielding with EMP (electromagnetic pulse) survivability and will also provide an environmental seal.

A flat, silicone sheet material, comprising a solid silicone rubber, embedded with Monel or aluminium metal wires orientated perpendicular to its surface. Excellent RFI/EMI/EMP shielding performance is achieved as the material has a wire density of up to 140 wires / CM² in solid silicone providing an environmental and RFI / EMI seal when clamped between two metallic surfaces. These wires are crimped to aid compression and are chemically bonded to ensure their retention in the silicone/fluorosilicone carrier. They will also penetrate most light oxide layers, ensuring a low contact resistance path when suitably compressed.

A choice of solid closed cell silicone, soft solid silicone, sponge silicone and solid fluorosilicone variants along with different wire counts in monel or aluminium are available allowing this product to be used in a wide range of applications to match galvanic compatibility and contaminate fluid resistance.

Kemtron have developed new grades of soft silicone material to fulfil a need that meets the performance of our sponge materials but with improved environmental sealing qualities. We have achieved this by using a very soft solid silicone with a reduced wire count of 100 wires per cm². The advantages of these materials over silicone sponge are that we can manufacture sheet widths of 225mm with a minimum thickness of 0.8mm. The material consistency of soft solid silicone is much better than silicone sponge as there is no uneven cell structure that may affect moisture ingress and closure force.

Availability

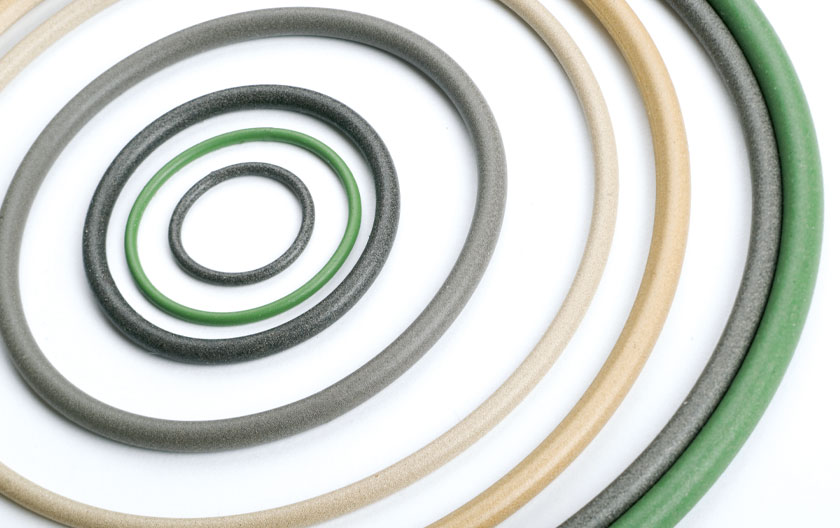

- Die-cut gaskets.

- Large fabricated gaskets.

- Virtually any flat shape can be produced.

- Sheet material.

- Strip material available in continuous lengths.

- Self-adhesive backing to allow for easy assembly.

- Gaskets can be fitted with compression limit stops or collars.

- Small gaskets can be punched in one operation, keeping production costs to a minimum.

- Larger gaskets can be produced cost effectively and without the constraint of sheet size limitation from strips of material fabricated into the required finished shape, thus avoiding waste material from the centre of the gasket.

- A fluorosilicone version is available for use in environments where fuels / oils / hydraulic fluids and other contaminants are present.

- Solid Silicone 410/420, for use in applications where higher compression forces allow for better environmental sealing.

- Soft solid silicone 470/480 or silicone sponge 430/440 for applications that require lower compression forces.

- Monel Wire in Solid Silicone (410)

- Aluminium Wire in Solid Silicone (420)

- Monel Wire in Silicone Sponge (430)

- Aluminium Wire in Solid Sponge (440)

- Monel in Solid Fluorosilicone (450)

- Aluminium in Solid Fluorosilicone (460)

- Monel Wire in soft solid Silicone (470)

- Aluminium Wire in soft solid Silicone (480)

A choice of solid silicone, soft solid silicone, sponge silicone and solid fluorosilicone variants along with different wire counts in Monel or aluminium are available allowing this product to be used in a wide range of applications to match galvanic compatibility and contaminate fluid resistance.

- A good solution for achieving RFI / EMI / EMP and environmental sealing in a single gasket.

- Ideal for use as access panels, seals, connector gaskets etc.

- Good conformity to allow for uneven surfaces.