RFI Shielding and EMI Shielding

We are an established company who are experts in RFI/EMI shielding with a global reputation for quality, performance, service and reliability in demanding industries including defence, aerospace, IT, telecommunications, medical and industrial electronics.

Trust Kemtron for high performance RFI/EMI shielding for extreme climatic, environmental and operational conditions.

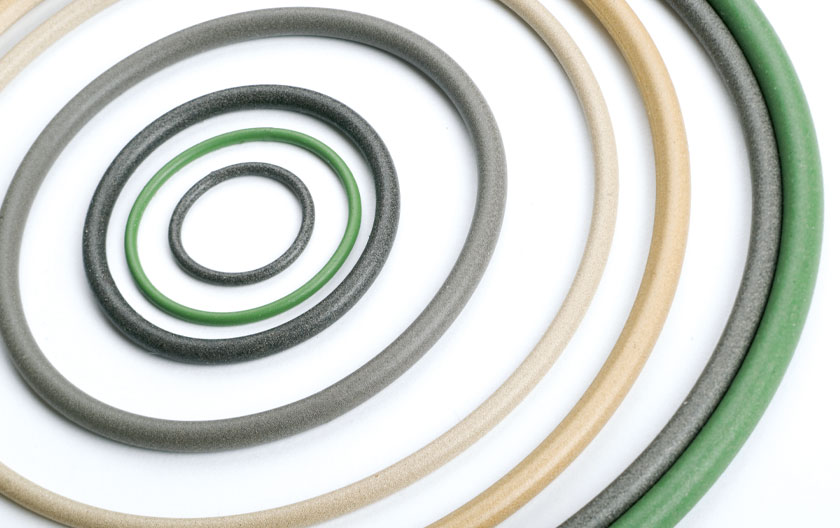

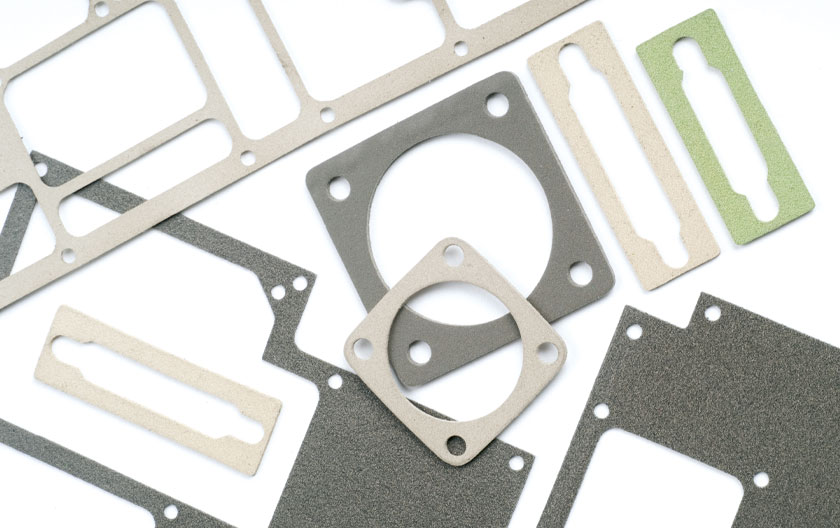

Manufacturers of RFI/EMI Shielding Gaskets & Components

Kemtron helps customers meet their RFI/EMI shielding and environmental sealing requirements with innovative RF solutions that enhance product performance, reduce through life costs and ensure regulatory conformance. We have achieved a global reputation for quality, performance and reliability, with an enviable track record in demanding industries such as defense, aerospace, information technology, communications and electronics.

Kemtron has provided a specialist service in EMI Shielding, RFI Shielding, & EMI shielding gasket and component solutions for over 30 years and has developed unparalleled experience and expertise in design, manufacture and support. By working in partnership with customers from an early stage, we help them optimise their shielding programmes while concentrating on their core business.

Latest from Kemtron

Keep up to date with our news updates, covering product development, industry highlights and Kemtron’s attendance at RFI/EMI focused trade shows.

Manufacturing

Our dedicated manufacturing facility and team produce materials and components to your needs.

Certifications