Electrically Conductive Elastomer Extruded Profiles

Conductive Elastomers are fully cured silicones or fluorosilicone loaded with electrically conductive particles providing superior EMI/RFI shielding performance combined with excellent environmental sealing. The various conductive fillers are designed to ensure galvanic compatibility whilst providing low contact resistance between mating surfaces.

Kemtron manufacture a wide range of extruded profiles from our standard tooling. We are also able to produce to your exact requirement with minimal tooling cost.

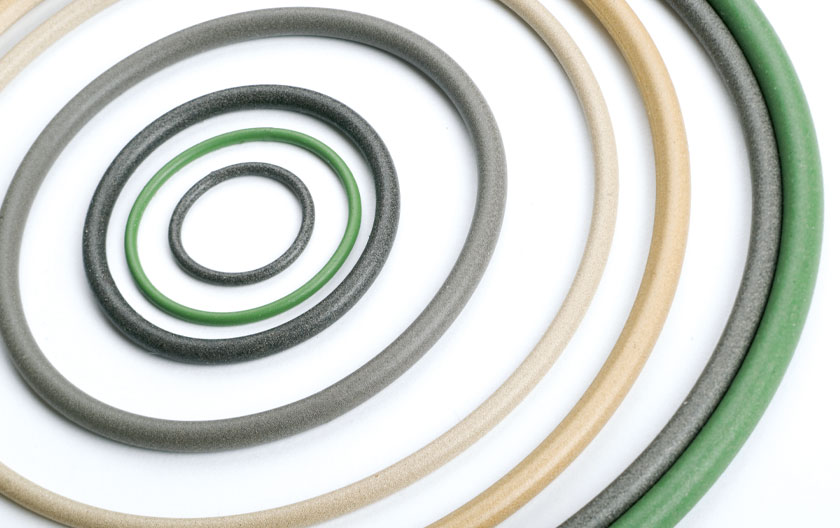

Extruded profiles are available in continuous lengths, cut lengths or fabricated to your requirements, such as O-Rings or rectangles by vulcanizing the joints. The vulcanising process uses the same conductive polymer compound ensuring complete electrical conductivity is maintained across the joint.

Performance

Kemtron’s Electrically Conductive Silicone Elastomer gasket material tests are performed in house and by external laboratories all using calibrated equipment, testing to the standard specified in MIL-DTL-83528. Kemtron offer the performance data and methods of testing to MIL-DTL-83528 for comparison only.

All of Kemtron’s test certificates and reports are available upon request. The results are obtained in laboratory conditions and should be used as a guide only. Customer hardware and many other factors are beyond our control. Therefore, customers should perform their own tests to ensure suitability of the product for the desired performance.

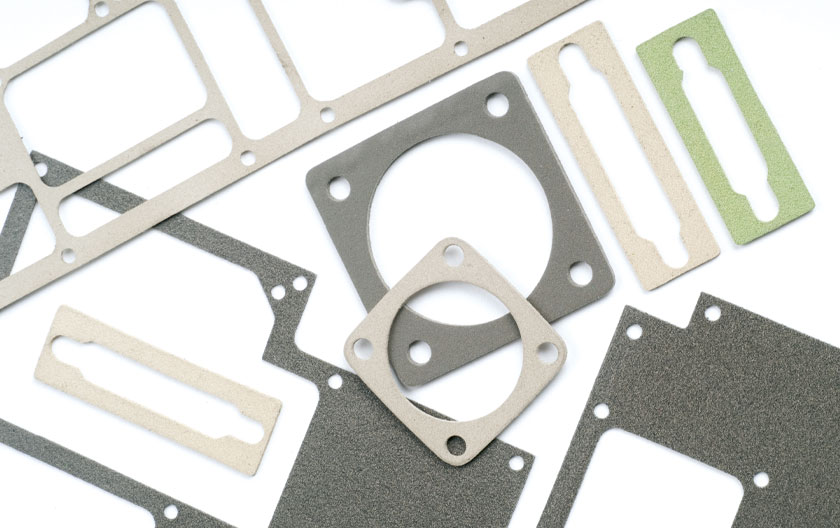

Profiles

Tube, Cord, Solid D, Hollow D, Channel, Strip and custom profiles.

- Silver-plated aluminium in silicone or fluorosilicone

- Silver plated copper in silicone or fluorosilicone

- Silver plated glass in silicone or fluorosilicone

- Nickel coated graphite in silicone or fluorosilicone

- Pure nickel in silicone or fluorosilicone

- UL94V0 grade of nickel coated graphite in silicone

Extruded profiles are normally mounted into grooves or channels of a clam shell style enclosure, the groove will hold the conductive Silicone gasket strip in place and also provide a compression stop to prevent the custom gasket from being over compressed when the enclosure is closed, another advantage is that with metal to metal contact of the 2 faces of the clam shell will enhance shielding effectiveness.

Flat strip profiles can be applied as a surface mount gasket, electrically conductive or non-conductive self-adhesive backing can be applied to the gasket strip but this should only be considered as an aid to assembly.

- Industrial controls

- Instruments

- Military equipment

- Avionics

- Medical electronics

- Electronic equipment enclosures’