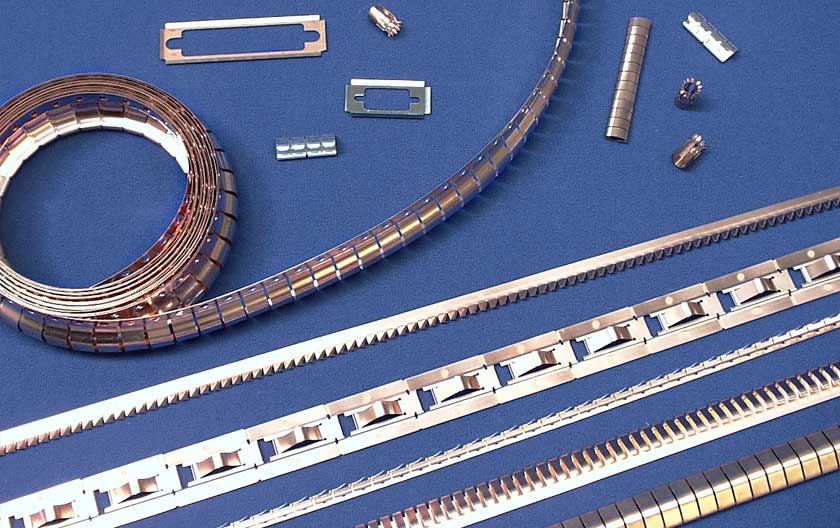

Board Level Shielding Cans

PCB shielding cans provide effective isolation of board level components. Photo etching is the most cost-effective production method for small to medium quantities and being custom made, the cans can be manufactured to incorporate a range of design features to suit individual applications.

Custom designed shielding cans are manufactured by photo etching or stamping, which is then folded and soldered or tabbed to form a continuous shield. They can have a removable or a fixed integral lid and they are then mounted on a PCB covering single or multiple components to provide excellent EMI and RFI shielding. Cans can be supplied to suit through hole or surface mount assembly. Internal dividers can be added to most designs and ventilation and access holes can be incorporated in both lids and fences.

Bespoke cans can be produced quickly to suit particular applications and provide a more effective solution than a standard product. Photo Etching is a flexible process offering a cost-effective product with quick turn round times. Cans be supplied flat for self-folding with etched fold lines or ready folded.

Stamping and pressing is a more expensive process due to tooling costs but offers high volume capability with low unit costs and are only available ready folded.

Cans can be supplied tape and reeled for automated assembly.

A wide range of materials and finishes are available, please enquire for further details.

PC board screening cans present an effective solution to the isolation of board level components and can provide individual or multi-cavity shielding over components on a PCB.